Benelux

United Kingdom

India

Slovakia

USA

Brazil | EN

Contact

Downloads

Benelux

United Kingdom

India

Slovakia

USA

Benelux

United Kingdom

India

Slovakia

USA

Our expansion joint, flexible metal hose, metal bellows and spring and constant hanger solutions are ideal for every application in plant engineering and construction.

Our variable and targeted pipe bracket products are designed based on the two pipeline construction calculation programs Intergraph CAESAR II and Sigma Rohr2. Our specially adapted design tool FLEXPERTE has the required interfaces to transfer the product specifications directly into the planning and design as 3D CAD models.

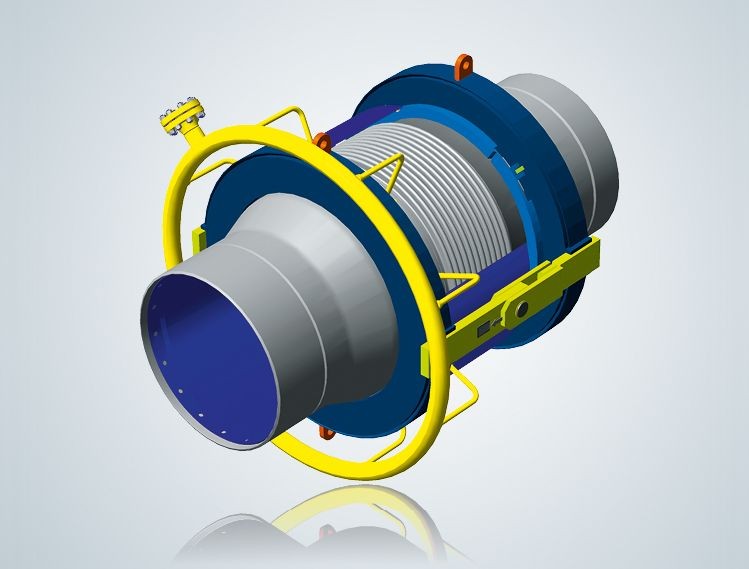

Material and engineering challenge in the high-temperature field

In order to protect an expansion joint from extreme temperatures, either a refractory lining is inserted inside (cold wall design) or high-temperature resistant materials such as Alloy 800H or Alloy 625 are used (hot wall design). For the refractory lining, hexmesh structures or stainless steel anchors are welded in and cast with special concrete and metal reinforcement if necessary. Insulated inner sleeves in the area of the metal bellows protect against the high medium temperatures.

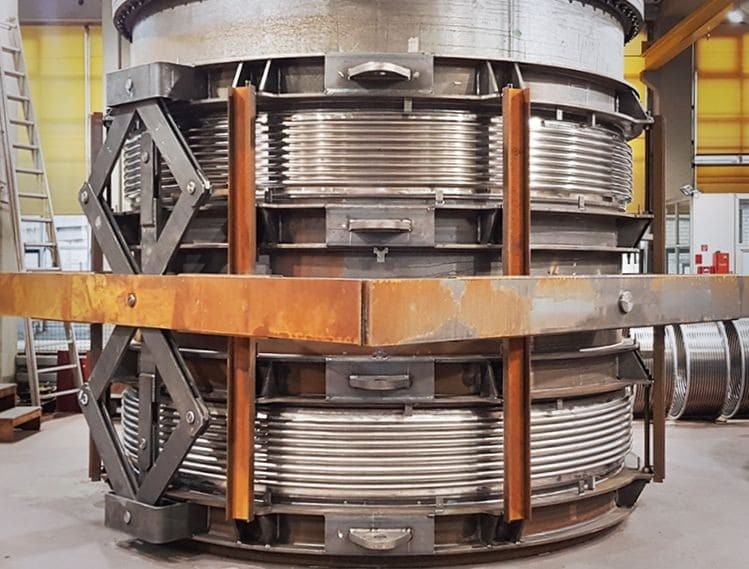

Since concrete-lined universal expansion joints are very heavy, pantographs are used here as restraint hardware. They prevent the bellows from buckling due to the weight of the intermediate pipe. At the same time, the pantograph distributes the loads evenly over the bellows elements.

Witzenmann is one of the few companies approved to supply Catofin plants in the high temperature field. With intelligent engineering and patented solutions, we have achieved a technological lead in this field.

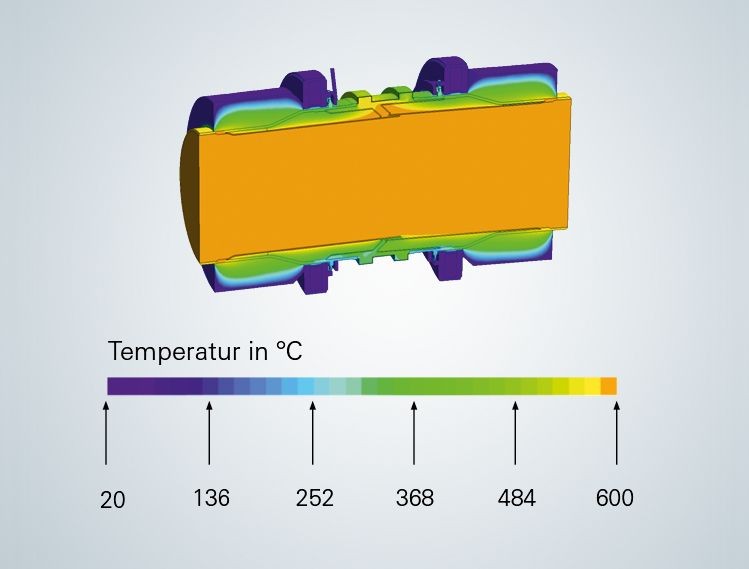

The 3-D CFD (computational fluid dynamics) calculation is used to calculate pressures, temperatures and flow velocities of moving media within fixed geometries. Here for an expansion joint with purged inner sleeves to calculate the temperature and flow distribution of the injected propane gas as barrier flow.

Use our FLEXPERTE tool to configure products, quickly and easily, to meet your individual requirements.

Details:

FLEXPERTE: The design program for the Witzenmann Group's entire product range with function-specific subdivisions

Drawing data, including complete 3D CAD drawings, is stored alongside the calculation formulae. With PDS and PDMS interfaces, the program is versatile and universally usable.